Optimal Testing

Porsche exclusively used digital testing for the all-electric Cayenne until the pre-production vehicles were available. However, the human factor remains essential: In the final test-drives, the drivers pushed the SUV to its limits – in icy cold and blistering heat.

Faster, more efficient, more digital. This is the goal for all new Porsche models. And for the all-electric Cayenne, which will soon be offered alongside the combustion engine and hybrid versions of the SUV series, this three-way approach also applies to testing: For the first time, Porsche has developed a completely new generation without the use of early prototypes.

Expert:

Sascha Niesen, team lead for complete vehicle testing in Weissach, was involved throughout the development.“It was the first project where we were able to start pre-series production immediately after virtual testing of the whole vehicle,” says Sascha Niesen, team lead for complete vehicle testing at the Porsche Development Centre in Weissach. The building stage – as the phase in which the prototypes are individually built is known internally – could be skipped entirely. Around 120 test vehicles, which are time-consuming to produce, were largely replaced by digital versions. The use of simulations and artificial intelligence has dramatically changed – and shortened – vehicle testing. The engineers were able to send virtual prototypes off on digital test laps during the construction phase. Three essential prerequisites for this were already well established at Porsche.

First, detailed, precise knowledge of the outside world: The Nürburgring has been completely digitized, including all track surface characteristics, as have some everyday roads with different surfaces and off-road terrain – each of which can be virtually combined with any type of climate and weather conditions. The second prerequisite: experience.

“We can draw on the unique knowledge of people who have built up decades of expertise in real-world testing,” explains Niesen. “They can judge exactly how a vehicle needs to behave if it is to bear the Porsche name.” And thirdly, the level of detail in the databases and processing power have improved to such an extent that real-time simulations have now become possible.

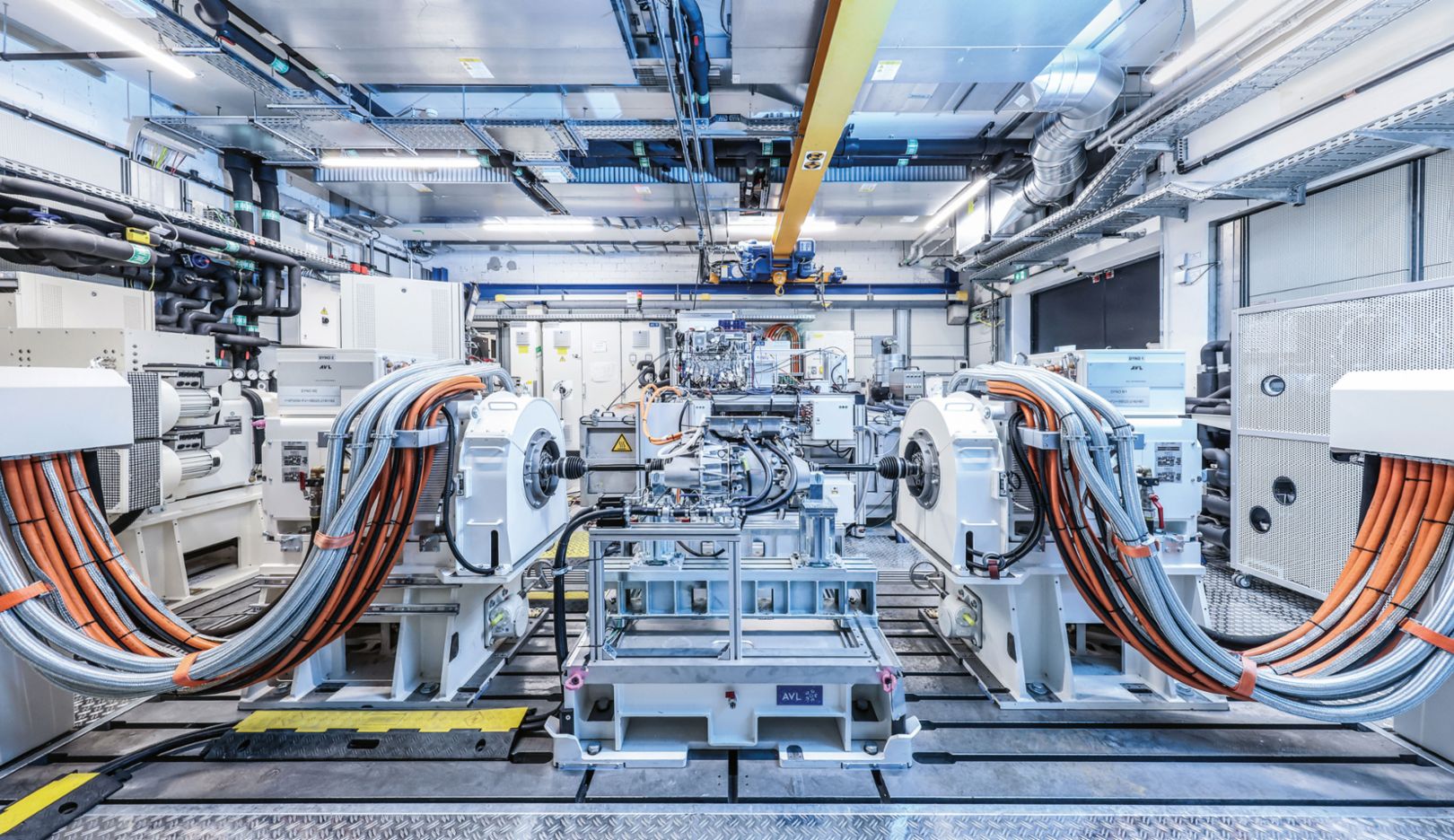

The engineers were not only able to create a virtual representation of the Cayenne, but could also put it through its virtual paces. During a development phase in which components initially existed in digital form and so could be easily modified, the experts used virtual reality (VR) to get an initial impression of the future SUV generation. The results of the digital testing were validated through bench tests involving real components. One area of focus of this combination of virtual and physical testing was on the interaction between the battery and drivetrain, aerodynamics, and air-conditioning. A wide range of new technologies have been incorporated into the all-electric SUV. A brand-new integrated test bench was developed for the project. This allowed the drive, battery, energy management system, and charging system all to be tested together under realistic conditions.

Vehicle-free development:

On the integrated test bench, simulation and physical systems such as the drive, battery, thermal management system, and charging system were brought together along with their control units, enabling tests to be conducted under realistic conditions.The four powerful synchronous motors on the test bench can be programmed to precisely simulate different road conditions, acceleration resistance, and forces occurring during recuperation and braking. “The technology is so sophisticated that we can even simulate different asphalt surfaces or tire slip,” says engineer Marcus Junige. Environmental conditions can also be fully simulated. Testing can incorporate the heating or cooling of individual components right through to the complete test setup as well as the generation of aerodynamic conditions. “Our testing programs are unique in terms of the standards they adhere to and compared to those of our competitors,” says Junige. One spectacular example was a lap on the Nürburgring Nordschleife – pushing the vehicle to its limit. The virtual prototype provided the necessary input, with all simulated impulses relayed to the integrated test bench in real time.

“The vehicle has to deliver maximum performance at all times and under all conditions as soon as the driver needs it,” Junige explains. “Maximum current release” is quite a stressful concept with regard to thermal management of high-performance vehicles. To ensure the battery is kept in top condition whatever the situation, the heating and cooling systems are more powerful than those in any electric Porsche to date. At each point of the lap around the Nürburgring, the values measured on the integrated test bench were compared with the previous calculations for the digital twin. This validated the accuracy of the simulation, with only minor deviations identified. These were resolved by reviewing the physical test results and adjusting the models or model parameters.

Real-world testing:

After the virtual tests, the engineers put the pre-production model through its paces in the desert.For the driver, reliability is important in every situation, including – and especially – when charging. “Regardless of what type of drive the Cayenne has just been on, it always needs to be ready for fast charging,” explains Junige. Once the driver confirms the charging station they’re planning to go to in the system, the Cayenne calculates the optimal preparation. “A traffic jam en route, for example, means that temperature adjustment can wait until later and can be carried out more slowly. This saves energy,” Sascha Niesen explains. In the virtual testing program, all probable situations before and during fast charging were simulated and tested on the test bench using real components.

However, the virtual testing program for the all-electric Cayenne involved far more than just recording fast laps around the Nürburgring or charging under extreme conditions. “Essentially, the difference between Porsche testing and how other manufacturers do it is that Porsche tests a very wide range of driving situations,” says Marcus Junige. Dictated by reality, as Sascha Niesen explains, “we need to examine everything that the customer can possibly do with the vehicle.” And no other Porsche is used in as many different ways as the Cayenne: It is a luxury SUV and a sports car, a towing and off-road vehicle, a family car, and a company car. “No electric vehicle has ever had so many different demands placed on it all at once,” says Marcus Junige. And the test engineers were in for a surprise here.

Adventurer:

The Cayenne is ready for practically any type of usage. Here: the final off-road tests on a course in Spain.During the simulation, the Cayenne was impressive in how it was able to handle various different inclines. But when the team took the first pre-production vehicles out for testing, they were even more impressive in reality. “A real highlight was how this car managed to go up the sand dunes,” says Sascha Niesen. “We didn’t expect that based on our findings.” The finely tuned electric drive allows propulsion to be regulated, enabling the Cayenne to effortlessly climb sand dunes from a standing start. “With a combustion engine, you would first need to build up momentum in order to climb up there,” the developer says. The electric drive, on the other hand, generates its full torque from the very first revolution. At the same time, minimal speeds of one or two kilometers per hour are also possible – “as though there were an infinitely large gear reduction,” as the engineer explains. Driving in the dunes also requires a lot of engine power. This is a specialty of the Cayenne. “We recorded acceleration values on par with super sports cars,” says Sascha Niesen.

Acceleration from 0 to 100 kmh was measured at less than three seconds. At the very top of the requirements for the Cayenne Electric was that it be easy to drive and control at all times. This was examined countless times during the simulation, “but in reality, it takes a human to apply the finishing touches.” Until now, early prototypes were used for this. Thanks to the advanced level of development, this phase could now be easily transferred to the actual pre-production vehicles. Traditionally, the Nürburgring served as the barometer for fine-tuning. The human driving experience is still more sensitive and influenced by more factors than any simulation can replicate. Ultimately, driving dynamics feedback is also determined by the coefficient of friction of the tires. “The transition from static to sliding friction in the boundary area is very difficult to represent virtually,” says Niesen. Although virtual testing allows the intermediate step involving early prototypes to be skipped, pre-production vehicles are still essential for Porsche.

Around 1,000 vehicles were built in the pre-production stage, three quarters of which were for final testing. This significant quantity is due to the large number of variants involved, multiplied by two body styles. “The car needs to reproduce in reality what it achieved in the simulation,” Niesen explains.

And this it did: In arctic cold and scorching desert heat, on and off roads all around the world, on test benches, and in crash labs. In hot regions such as the Gulf States and Death Valley in the USA, where temperatures can reach 50 degrees Celsius, functional testing was necessary for the air-conditioning and thermal management systems for the battery and drive, for example. In temperatures of minus 35 degrees Celsius in Finland, the pre-production vehicles were put through their paces with tests examining cold starts and air-conditioning, traction, handling, braking behavior, and driving dynamics control system performance. And the all-electric Cayenne needed to be able to fast charge easily in the extreme conditions at both ends of the scale – no other manufacturer demands as much from its vehicles as Porsche. Endurance testing simulated the service life of a vehicle under extreme conditions rarely experienced by customers. Under everyday conditions, the vehicles each completed more than 150,000 kilometers in shift operation within a few months – in city traffic, on rural roads, and on autobahns.

Digital development:

Before the pre-production vehicles were built, the Cayenne Electric was tested virtually and on the test bench.Result: The shift toward more simulations with reduced physical testing has proven successful. “The time was right for this,” says Niesen. “And this project presented the perfect opportunity.” With great success: The development time needed for the all-electric Cayenne was 20 percent faster than following a conventional approach. And also more environmentally friendly thanks to the reduced use of materials. Faster, more efficient, more digital.

Consumption data

911 GT3 RS

Cayenne Turbo Electric

-

22.4 – 20.4 kWh/100 km

-

0 g/km

-

A Class