Hard like Diamond

It doesn’t rust and produces hardly any brake dust. The Porsche Surface Coated Brake (PSCB) will debut as a standard feature of the new Cayenne Turbo.

Consumption data

Cayenne Turbo

Fuel consumption combined: 11.4 – 11.3 l/100 km

CO2 emissions combined: 261 – 258 g/km (as of 07/2020)

Matthias Leber

Head of the brake division and the mastermind behind the PSCB.Ever heard of WIDIA? Dr. Matthias Leber flashes a knowing smile. As a mechanical engineer and brake expert at the Porsche Development Center in Weissach, he’s able to develop future-oriented products precisely because he’s familiar with the past. And that includes WIDIA. Developed in the early twentieth century, this was the trade name for an amazingly hard material with a crucial main component: tungsten carbide. The name is an acronym for wie Diamant, which is German for “like diamond.” Leber is very well versed in materials and their properties. He gazes proudly at an impeccably clean and sparkling brake disc. Even though it’s used, it could be mounted on the wall like a mirror. Tungsten carbide doesn’t rust or tarnish. But regardless of how attractive this brake is, the most important thing about it is its performance.

The Porsche Surface Coated Brake (PSCB), which is celebrating its debut as a standard feature in the new Porsche Cayenne Turbo, is nothing less than a worldwide first. Its surface consists of tungsten carbide (chemical formula: WC). Tungsten and carbon form a mixed crystal so hard that it can be used to cut glass. Tungsten carbide is one of the hardest materials in the world after diamond, and around ten times harder than gray cast iron—which is precisely what makes it so interesting to brake engineers.

Sounds like alchemy

What would happen if there were a brake that functioned nearly as well as a ceramic brake and had the same thermal stability but cost only about one-third as much, didn’t need racing pads, showed much less wear than a conventional gray-iron brake, produced hardly any brake dust, and didn’t rust? That sounds like alchemy—yet it’s serious technology from Porsche. “But believe me, it was a long road getting here. Otherwise we would have offered it ages ago,” says Leber. Amazing developments don’t just fall from the sky. They’re the product of dedicated development work.

New technology developed for racing is often transferred to road vehicles. One example would be the Porsche Ceramic Composite Brake (PCCB), which is a master at deceleration and the absolute benchmark in its field. Modern gray-iron brakes are no slouch either. But there was a need for a hybrid of these two types—for those especially powerful Porsches that don’t necessarily hit the racetrack every day. The solution was obvious to Leber and his team: a carbide coating. For why shouldn’t tool steel with a century-long track record work just as well for a brake disc?

Simply put, a brake disc made entirely of tungsten carbide would cost as much as several sets of ceramic brakes. Moreover, the technology wasn’t sufficiently advanced to bind tungsten carbide to a substrate—such as gray iron. But following a lengthy series of tests in close collaboration with Bosch/Buderus, Porsche made a breakthrough. A gray-iron disc was laser-processed to offer structure, then galvanized with an interlayer. The interlayer acts like a flexible bond to relieve the differential thermal extension of gray iron and tungsten carbide, which is then applied in a spectacular manner: a high-velocity oxy-fuel spraying process shoots tungsten carbide particles at the disc at supersonic speeds. For a moment, it looks like a Star Wars lightsaber is firing around the disc. The result is a coating around one hundred micrometers thick—but it still doesn’t do the trick on its own. Now what it needs are very special brake pads.

“Even we were surprised by how beautifully it worked.” Matthias Leber

Searching for the right composite

“The pads required at least as much development effort,” says Leber. Laser technology and high-precision, automated production processes for a new type of disc are one thing. Pads with the right composite are another. A surface as smooth as a mirror needs a special pad that’s adhesive. Imagine running your finger with light pressure over a mirror; it doesn’t slide uniformly but instead keeps sticking for an instant. However, an overly soft pad on a very hard surface would wear down too quickly at high disc speeds. So the engineers added some very hard materials to the pad: microscopic particles that penetrate the tungsten carbide coating. These pads positively cling to the disc.

Microscopic anchors

“The result surprised us all,” says Leber. “We already knew that the brake would be good, but the first tests exceeded all our expectations.” Thanks to the smooth surface, the full pad immediately starts covering the disc at low speeds. You could compare it to the difference between a vinyl record and a CD: unlike gray iron, tungsten carbide has hardly any grooves and is smooth as a mirror, so there are no hollows to reduce the total amount of surface area. When greater stopping power is needed at high speeds, the hard components of the pad throw out their microscopic anchors. “That, of course, means wear and tear,” says Leber. “It also means brake dust, but 90 percent less than what you’d get with a gray-iron brake.” Moreover, the tungsten carbide discs have a service life 30 percent longer than their gray-iron counterparts. This puts their performance levels close to those of the PCCB, but at only one-third of the cost of the ceramic brakes. And the new brakes feel like the PCCB in practice. The pedal force remains constant, even when the brakes are hot. These brakes don’t show the dreaded fading behavior at high temperatures. On the contrary, they work all the more crisply at temperatures above 600 degrees Celsius.

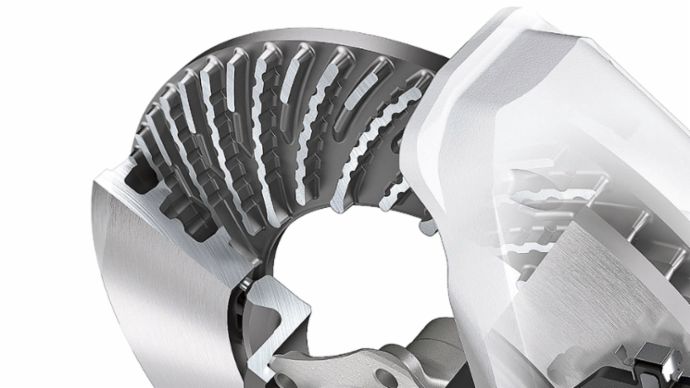

Brake disc and caliper

Coated lightweight gray-iron brake disc with a ten-piston fixed caliper.

PSCB brake pads

They have a newly developed special material.

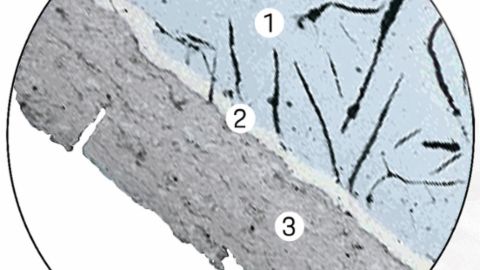

PSCB—a global first

1. Thermally treated surface

Lasers structure, abrade, and clean the gray-iron core.

2. Ductile interlayer

Nickel applied in a galvanic process helps bind the gray iron and tungsten carbide.

3. Hard-metal coating

This consists of tungsten carbide, flame-sprayed on at high velocity.

Clean as a whistle

After around six thousand kilometers of normal use, the brake pads have polished the surface of the disc to a shine. Their color then matches the white ten-piston fixed calipers in the front and the four-piston fixed calipers in the rear, whose technology is familiar from the PCCB. But why white? Leber laughs. “If a brake produces practically no dust, you want to advertise that fact. My color proposal met with a lot of initial resistance.” But after thousands of kilometers, the brakes on the new Porsche Cayenne test vehicles are still clean as a whistle.

The PSCB will start as standard equipment only in the new Cayenne Turbo. It’s available as an option for all other new Cayenne models. Is the PSCB the perfect combination of performance, aesthetics, and cost effectiveness—and thus the holy grail of brake development? Leber shakes his head. “As electrification makes ever greater advances in automotive engineering, it’ll also bring new types of brakes. Recuperation, for example, is a completely non-wear type of deceleration, which makes it all the more interesting, because at some point we’ll be able to use it for 90 percent of all standard braking action. We have to keep working on it.” After all, fast cars need fast brakes. So Porsche brakes can never be fast enough.